Window Well DIY Installation Guide

Complete guide for DIY window well installation meeting Ontario Building Code. Learn proper sizing, drainage requirements, installation steps, and safety covers. Professional instructions for creating safe, code-compliant basement window wells.

Key Requirements

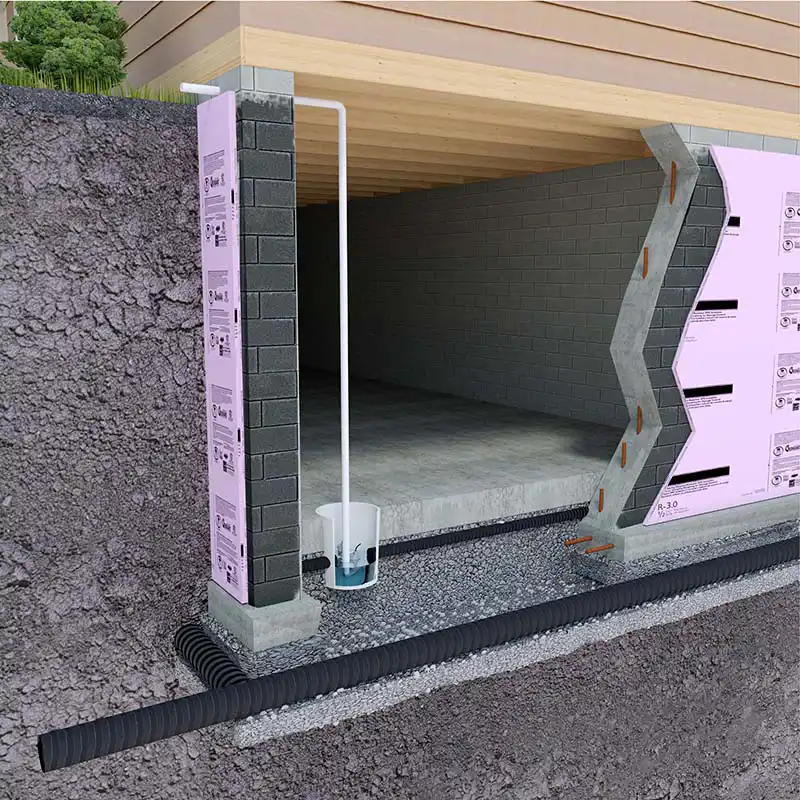

✓ Drainage connection mandatory

✓ Egress wells 760mm projection minimum

✓ Ladder required over 900mm deep

✓ Covers must support 40 lbs/sq ft

✓ Clear stone drainage essential

Service Areas

We provide professional window well installation throughout the Greater Toronto Area. View our complete service area coverage →

Remember: Window wells without proper drainage are just water collectors against your foundation. Focus on drainage first, everything else second. When in doubt, consult professionals.