Waterstop Installation Services

Professional waterstop systems prevent water infiltration through concrete construction joints. Essential for basements, tunnels, water treatment plants, and parking structures.

What Are Waterstops?

Waterstops are continuous water barriers embedded in concrete joints to prevent water passage. Critical for:

- Construction joints (cold joints)

- Expansion joints

- Contraction joints

- Pipe penetrations

- Wall-floor connections

Types of Waterstops

PVC Waterstops

Most Common Solution

Types available:

- Dumbbell (centerbulb) - for expansion joints

- Ribbed - for construction joints

- Tear web - for control joints

- Base seal - for wall-floor joints

Sizes:

- 4" to 12" widths

- 3/8" to 3/4" thickness

- Various profile shapes

- Custom lengths

Benefits:

- Chemical resistant

- Long service life

- Moderate movement

- Cost-effective

- Easy splicing

Rubber Waterstops

For High Movement Joints

Applications:

- Settlement-prone areas

- Seismic zones

- Temperature extremes

- Chemical exposure

- High water pressure

Features:

- Superior flexibility

- 50%+ movement capability

- Chemical options available

- Extreme temperature range

- Field vulcanizing

Swelling Waterstops

Hydrophilic Technology

Types:

- Bentonite-based strips

- Hydrophilic rubber

- Composite products

- Coated types

Advantages:

- Easy installation

- Irregular surface capable

- Self-healing properties

- No special forming

- Retrofit applications

Injectable Waterstop Systems

Repairable Solutions

Components:

- Perforated injection hose

- PVC or rubber flanges

- Injectable resins

- Access ports

Benefits:

- Post-construction repair

- Guaranteed seal

- Pressure testing

- Critical applications

- Long-term reliability

Installation Process

1. Joint Preparation

- Clean joint surfaces

- Remove debris/laitance

- Check joint alignment

- Verify dimensions

- Mark centerline

2. Waterstop Positioning

- Center in joint

- Secure positioning

- Check alignment

- Maintain profile

- Protect during work

3. Securing Methods

For PVC/Rubber:

- Hog rings/clips

- Tie wires

- Grout split

- Adhesive strips

- Manufactured brackets

For Swelling Types:

- Adhesive application

- Mechanical fasteners

- Primer if required

- Overlap joints

- Protection tape

4. Concrete Placement

- Careful consolidation

- No segregation

- Full encapsulation

- Avoid displacement

- Proper vibration

5. Quality Control

- Visual inspection

- Position verification

- Splice integrity

- Concrete consolidation

- Documentation

Critical Applications

Water-Retaining Structures

- Water treatment plants

- Reservoirs

- Swimming pools

- Tanks

- Clarifiers

Below-Grade Construction

- Basement walls

- Tunnel segments

- Parking garages

- Elevator pits

- Utility vaults

Infrastructure Projects

- Dams

- Locks

- Culverts

- Bridge abutments

- Retaining walls

Joint Types & Solutions

Construction Joints

Where concrete pours meet:

- Wall to footing

- Wall to wall

- Slab to wall

- Column connections

- Pour breaks

Recommended:

- Ribbed PVC waterstop

- Swelling waterstop

- Injectable systems

Expansion Joints

Allow movement:

- Temperature changes

- Settlement

- Seismic movement

- Structural deflection

Recommended:

- Centerbulb PVC

- Rubber waterstop

- Surface-mounted seals

Pipe Penetrations

Seal around pipes:

- Link seals

- Rubber boots

- Cast-in sleeves

- Injectable collars

- Mechanical seals

Design Considerations

Waterstop Selection

Factors:

- Joint type and movement

- Water pressure

- Chemical exposure

- Installation conditions

- Service life required

Sizing Guidelines

- Joint movement amount

- Concrete thickness

- Water head pressure

- Safety factors

- Code requirements

Installation Details

- Splice procedures

- Corner fabrication

- T-intersections

- Transition pieces

- End terminations

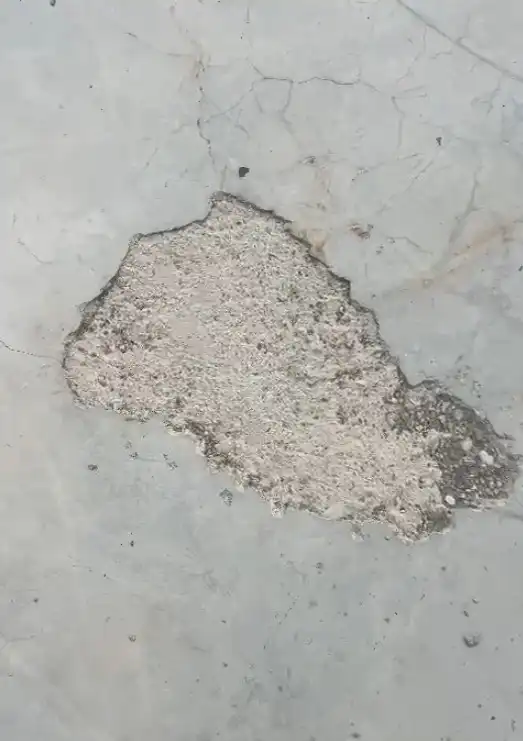

Common Problems & Solutions

Installation Errors

- Improper positioning → Use positioning devices

- Concrete segregation → Careful placement

- Splice failures → Proper welding/adhesive

- Displacement → Secure fastening

Performance Issues

- Leaking splices → Factory fabrication

- Joint movement excess → Larger waterstop

- Chemical attack → Material selection

- Installation damage → Protection measures

Quality Assurance

Material Standards

- ASTM D7032 (PVC)

- CRD-C 572 (Testing)

- NSF certification

- Provincial standards

- Project specifications

Installation Standards

- Manufacturer guidelines

- Engineering specifications

- Industry best practices

- QC procedures

- Documentation requirements

Cost Factors

Material Costs

- Waterstop type

- Size/profile

- Quantity ordered

- Special fabrications

- Accessories needed

Installation Costs

- Joint accessibility

- Concrete coordination

- Weather conditions

- Schedule constraints

- Quality requirements

Value Engineering

- Optimize types used

- Minimize splices

- Standard sizes

- Bulk ordering

- Efficient scheduling

Maintenance & Repair

Inspection Schedule

- Visual checks

- Leak monitoring

- Movement measurement

- Condition assessment

- Document findings

Repair Options

- Injection grouting

- Surface sealing

- Joint rehabilitation

- Waterstop replacement

- Protective coatings

Why Professional Installation

Critical Success Factors

- Proper selection

- Correct positioning

- Quality splicing

- Concrete coordination

- Experience matters

Risks of Poor Installation

- Water infiltration

- Structural damage

- Costly repairs

- Health hazards

- Legal liability

Get Expert Help

Our services include:

- Design assistance

- Material selection

- Professional installation

- Quality assurance

- Warranty protection

Call for Consultation: (437) 545-0067

Protect your investment with proper waterstop installation.