Slab & Foundation Construction Services

Expert concrete slab installation for basements, garages, and structural applications. Quality workmanship ensures level, durable, and long-lasting concrete floors.

Types of Slabs We Install

Basement Floor Slabs

Essential for Dry, Usable Space

Components:

- Compacted granular base

- Vapor barrier membrane

- Rigid foam insulation

- Reinforcement mesh/rebar

- Quality concrete mix

Features:

- Proper slope to drains

- Smooth, level finish

- Control joints

- Sealed penetrations

- Optional heating tubes

Process:

- Excavation/preparation

- Gravel base installation

- Vapor barrier placement

- Insulation (if required)

- Steel reinforcement

- Concrete pour/finish

Garage Floor Slabs

Built for Vehicle Loads

Specifications:

- 4-6" thickness minimum

- 3500+ PSI concrete

- Wire mesh or rebar

- Proper drainage slope

- Durable surface finish

Special features:

- Floor drains

- Slope to doors

- Expansion joints

- Non-slip finish

- Chemical resistance

Options available:

- Heated floors

- Epoxy coatings

- Integral color

- Exposed aggregate

- Polished concrete

Structural Slabs

Load-Bearing Applications

Types:

- Suspended slabs

- Post-tensioned slabs

- Composite deck slabs

- Waffle slabs

- Two-way slabs

Engineering includes:

- Load calculations

- Reinforcement design

- Deflection control

- Shear requirements

- Fire ratings

Slab-on-Grade

Ground-Supported Slabs

Applications:

- House additions

- Detached garages

- Sheds/workshops

- Patios

- Industrial floors

Key elements:

- Frost protection

- Thickened edges

- Proper subgrade

- Moisture control

- Joint placement

Construction Process

1. Site Preparation

- Excavation to depth

- Subgrade compaction

- Verify elevations

- Install utilities

- Form installation

2. Base Preparation

- Granular placement

- Compaction testing

- Fine grading

- Vapor barrier

- Insulation placement

3. Reinforcement

- Chair/support installation

- Rebar placement

- Mesh positioning

- Tie wire connections

- Inspection approval

4. Concrete Placement

- Mix design verification

- Systematic pouring

- Proper consolidation

- Level/screed

- Float finish

5. Finishing

- Bull float

- Edge work

- Control joints

- Surface texture

- Curing process

Technical Specifications

Concrete Mix Design

Standard mixes:

- Basement: 25 MPa minimum

- Garage: 30 MPa minimum

- Structural: 35+ MPa

- Exterior: Air-entrained

- Special: Fiber-reinforced

Admixtures used:

- Water reducers

- Accelerators

- Retarders

- Air entrainment

- Fiber reinforcement

Reinforcement Options

- 6x6 W1.4 wire mesh

- #3 or #4 rebar grids

- Fiber reinforcement

- Post-tension cables

- Structural steel

Joint Systems

Types and spacing:

- Control joints: 10-15’ spacing

- Expansion joints: At walls

- Construction joints: Pour breaks

- Isolation joints: Around columns

- Sealant types: Various

Specialized Services

Radiant Floor Heating

In-slab heating systems:

- PEX tubing layout

- Manifold installation

- Insulation requirements

- Control systems

- Energy efficiency

Benefits:

- Even heat distribution

- Energy savings

- Comfort

- Snow melting

- No visible equipment

Decorative Concrete

Finish options:

- Stamped patterns

- Exposed aggregate

- Integral color

- Acid staining

- Polished concrete

Applications:

- Basement floors

- Garage floors

- Patios

- Walkways

- Commercial spaces

Moisture Control Systems

Preventing problems:

- Vapor barriers

- Waterproof membranes

- Drainage layers

- Sump pits

- Perimeter drains

Testing available:

- Moisture testing

- Calcium chloride

- Relative humidity

- pH testing

- Adhesion testing

Cost Considerations

Price Factors

- Slab thickness

- Site accessibility

- Reinforcement type

- Finish requirements

- Special features

Typical Project Costs

- 500 sq ft basement: $4,000-$6,000

- 2-car garage: $6,000-$9,000

- 1000 sq ft addition: $12,000-$18,000

- Heated garage: $8,000-$12,000

Additional Costs

- Excavation: $50-$100/cubic yard

- Old slab removal: $3-$5/sq ft

- Radiant heating: $8-$12/sq ft

- Decorative finishes: $2-$8/sq ft

- Vapor barriers: $0.50-$1/sq ft

Quality Control

During Construction

- Subgrade testing

- Concrete testing

- Slump tests

- Air content

- Cylinder breaks

Finishing Standards

- FF/FL numbers

- Surface tolerance

- Joint spacing

- Crack control

- Appearance

Long-term Performance

- Proper curing

- Joint maintenance

- Surface sealers

- Regular inspection

- Warranty coverage

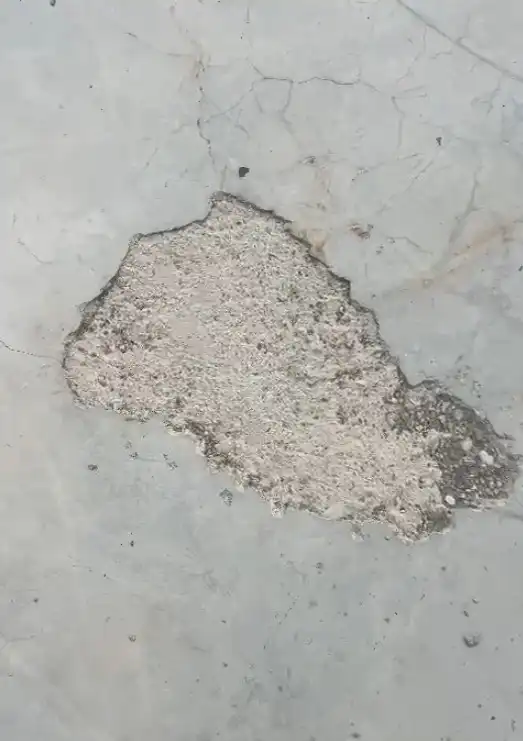

Common Problems Prevented

By Proper Design

- Cracking

- Settlement

- Frost heave

- Moisture issues

- Surface defects

By Quality Installation

- Uneven surfaces

- Premature wear

- Water problems

- Structural failure

- Costly repairs

Maintenance & Care

Initial Care

- Curing period

- Traffic restrictions

- Temperature control

- Moisture retention

- Protection measures

Ongoing Maintenance

- Joint sealing

- Crack repair

- Surface sealing

- Cleaning methods

- Preventive care

Green Building Options

Sustainable Materials

- Recycled content

- Local aggregates

- Fly ash/slag

- Reduced cement

- Permeable options

Energy Efficiency

- Insulated slabs

- Thermal mass

- Radiant barriers

- Reflective surfaces

- LEED points

Why Choose DrySpace

Our Advantages

- Experienced crews

- Modern equipment

- Quality materials

- Precise work

- Warranty protection

Project Management

- Clear scheduling

- Daily updates

- Clean sites

- Safety focus

- Final walkthrough

Get Started Today

Free estimate includes:

- Site evaluation

- Design consultation

- Material options

- Cost breakdown

- Timeline planning

Call Now: (437) 545-0067

Quality concrete slabs built to last a lifetime.