Types of Piling Systems We Install

Mini Piles (Micropiles)

Ideal for Underpinning and Tight Spaces

Mini piles are small-diameter (5-12 inch) piles perfect for residential underpinning projects. These versatile piles work in limited access areas where larger equipment cannot fit.

Features:

- High-strength steel casing

- Grouted for soil bonding

- Minimal vibration installation

- Works through existing foundations

- Capacity: 25-200 tons per pile

Applications:

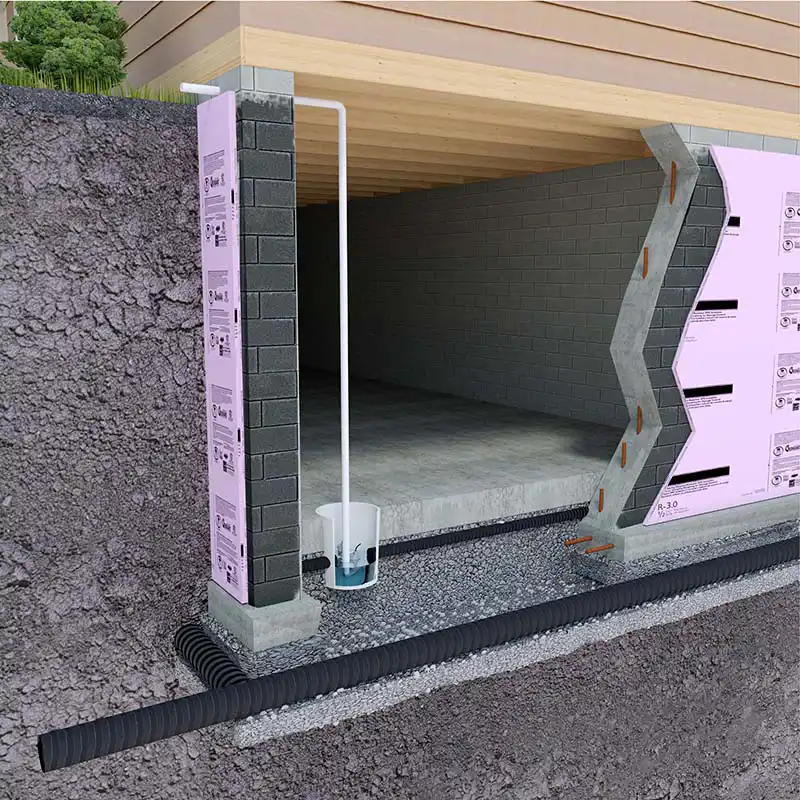

- Basement underpinning support

- Foundation stabilization

- Seismic retrofitting

- Historic building preservation

- Emergency stabilization

Helical Piles (Screw Piles)

Fast Installation with Immediate Loading

Helical piles feature steel shafts with helical plates that are literally screwed into the ground. Installation torque correlates directly to capacity, ensuring quality control.

Advantages:

- No concrete curing time

- Minimal site disturbance

- All-weather installation

- Removable if needed

- Predictable capacity

Best For:

- Temporary structures

- Boardwalks and decks

- Light commercial buildings

- Foundation repairs

- Solar panel arrays

Driven Piles

High Capacity for Major Projects

Traditional driven piles use impact hammers to advance steel or precast concrete piles to refusal. While noisy, they provide excellent capacity verification through driving resistance.

Types Available:

- Steel H-piles

- Steel pipe piles

- Precast concrete

- Timber (rare today)

- Composite materials

Typical Uses:

- Commercial buildings

- Bridge foundations

- Marine structures

- Industrial facilities

- High-rise construction

Drilled Piles (Caissons)

Large Diameter Deep Foundations

Drilled piles involve augering large holes and filling with reinforced concrete. These provide maximum capacity for major structures.

Specifications:

- Diameters: 24-96 inches

- Depths: Up to 100+ feet

- Reinforced concrete design

- Rock socket capability

- Extremely high capacity

Applications:

- High-rise buildings

- Bridge piers

- Major infrastructure

- Elevator pits

- Tower foundations