Mold-Free Basement Construction Guide

Complete guide to building mold-free basements using steel studs, rigid foam insulation, and smart vapor management. Learn why traditional methods fail and how modern materials create permanently healthy basement spaces.

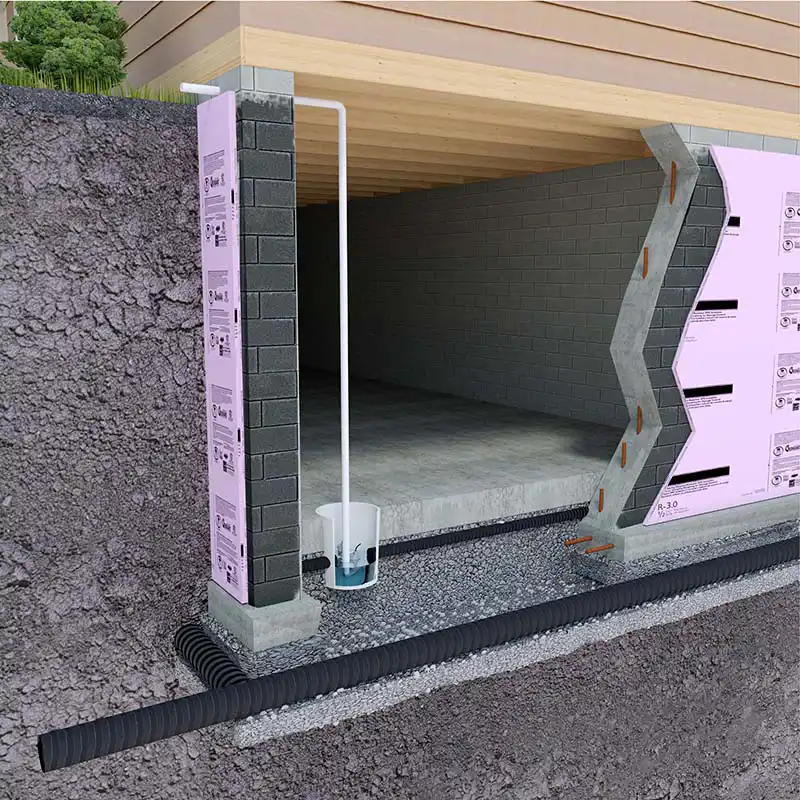

The Mold-Free System

Essential Components:

- Steel studs (no mold food)

- Rigid foam insulation (moisture resistant)

- Smart vapor retarders (adaptive)

- Mold-resistant drywall

- Proper humidity control (30-50%)

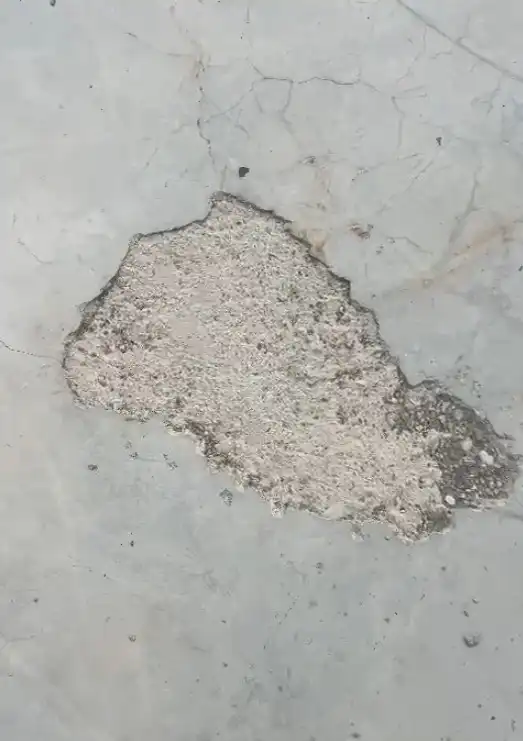

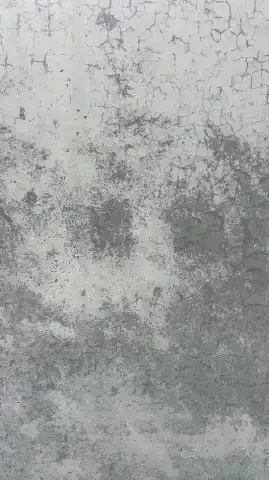

Why Traditional Methods Fail

Wood studs + fiberglass insulation + poly vapor barrier = mold growth

The Problem:

- Wood absorbs moisture

- Insulation traps water

- Vapor barriers create condensation

- Mold grows in 24-48 hours

Cost Comparison

- Traditional System: $4-5/sq ft (plus future mold remediation)

- Mold-Free System: $6-8/sq ft (one-time investment)

- Difference: $2-3/sq ft

- Value: Permanent health protection

Service Areas

Service Areas: Toronto, North York, Scarborough, Etobicoke, East York, York, Mississauga, Brampton, Vaughan, Richmond Hill, Markham, and surrounding areas.

Building a truly mold-free basement requires the right materials, proper installation, and ongoing moisture control. Don’t compromise on your family’s health or your investment. Choose materials that cannot support mold growth and build a basement that lasts forever.