Professional Formwork Construction

Expert concrete forming services for foundations, walls, and structural elements. Using modern forming systems for precision and efficiency.

Formwork Systems We Use

Panel Forming Systems

Modern Efficiency for Large Projects

Systems available:

- Aluminum panel forms

- Steel-framed plywood

- Modular panel systems

- Gang form assemblies

- Climbing systems

Benefits:

- Fast assembly

- Smooth finishes

- Reusable components

- Consistent quality

- Labor savings

Traditional Wood Forming

Custom Solutions for Unique Needs

Applications:

- Residential foundations

- Custom shapes

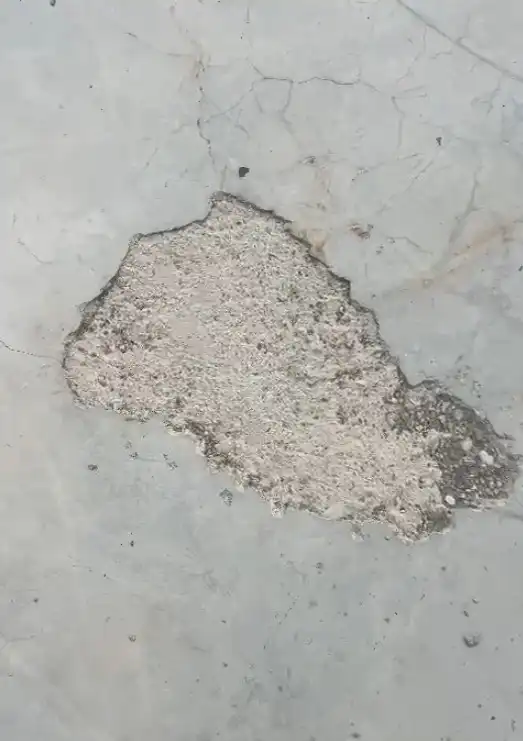

- Repair work

- Small projects

- Architectural details

Advantages:

- Fully customizable

- Cost-effective for small jobs

- Easy modifications

- Local materials

- Skilled craftsmen

Specialty Forming Systems

Advanced Applications

Types:

- Insulated Concrete Forms (ICF)

- Stay-in-place forms

- Fabric forms

- Slip forms

- Architectural forms

Services Offered

Foundation Formwork

Complete forming for:

- Footings and grade beams

- Foundation walls

- Pilasters and buttresses

- Step foundations

- Frost walls

Process:

- Layout and excavation prep

- Form assembly and bracing

- Steel reinforcement placement

- Concrete pour coordination

- Stripping and finishing

Wall Forming

Professional installation:

- Straight walls

- Curved walls

- Tall walls (up to 20')

- Architectural finishes

- Window and door bucks

Features:

- Plumb and straight

- Proper ties and braces

- Clean corners

- Smooth finishes

- Safety compliance

Structural Formwork

Complex forming for:

- Elevated slabs

- Beam and column forms

- Stair forms

- Equipment bases

- Architectural concrete

Custom Architectural Forming

Creating unique features:

- Radius walls

- Decorative elements

- Exposed aggregate

- Board-formed concrete

- Special textures

The Forming Process

1. Planning & Design

- Review structural drawings

- Calculate form pressures

- Design form layout

- Plan pour sequence

- Order materials

2. Form Assembly

- Set up work area

- Assemble panels/build forms

- Install form ties

- Place reinforcement chairs

- Install embeds

3. Alignment & Bracing

- Check dimensions

- Ensure plumb/level

- Install walers

- Diagonal bracing

- Secure all connections

4. Pre-Pour Inspection

- Verify dimensions

- Check reinforcement

- Inspect form tightness

- Review accessibility

- Safety inspection

5. Pour Support

- Monitor during pour

- Adjust as needed

- Vibration coordination

- Watch for movement

- Quality control

6. Form Removal

- Follow curing schedule

- Careful stripping

- Clean forms

- Repair any defects

- Prepare for reuse

Quality Standards

Form Requirements

- Structurally adequate

- Mortar tight joints

- Proper alignment

- Adequate bracing

- Safe working platforms

Tolerances

- Plumb: ±1/4" in 10'

- Level: ±1/4" in 10'

- Dimension: ±1/4"

- Alignment: 1/4" in 10'

- Finish: Class B minimum

Safety Standards

- Fall protection

- Proper access

- Load ratings posted

- Daily inspections

- Engineer approval

Formwork Design Factors

Load Calculations

Consider:

- Concrete weight (150 lb/ft³)

- Pour rate pressure

- Live loads

- Wind loads

- Equipment loads

Pour Rate Effects

- Temperature factors

- Concrete slump

- Pour height

- Vibration effects

- Setting time

Cost Factors

Variables Affecting Price

- Form type required

- Number of uses

- Complexity of shape

- Access conditions

- Schedule demands

Cost Breakdown

- Materials: 30-40%

- Labor: 40-50%

- Equipment: 10-15%

- Engineering: 5-10%

Ways to Save

- Reuse forms multiple times

- Standard dimensions

- Simplified designs

- Good planning

- Experienced crews

Special Services

Form Rental

- Daily/weekly/monthly rates

- Delivery and pickup

- Technical support

- Accessories included

- Training available

Engineering Services

- Form design

- Pressure calculations

- Shop drawings

- Stamped submissions

- Field support

Architectural Concrete

- Board-formed finishes

- Exposed aggregate

- Custom textures

- Form liners

- Color additives

Project Types

Residential

- House foundations

- Garage floors

- Basement walls

- Retaining walls

- Decorative features

Commercial

- Office buildings

- Retail spaces

- Parking structures

- Warehouses

- Industrial facilities

Infrastructure

- Bridge elements

- Culverts

- Sound walls

- Utility vaults

- Public works

Why Professional Forming Matters

Benefits of Expertise

- Proper design prevents failures

- Efficient use of materials

- Faster construction

- Better concrete quality

- Safety compliance

Risks of Poor Forming

- Form blowouts

- Poor finishes

- Dimensional errors

- Safety hazards

- Wasted concrete

Environmental Considerations

Sustainable Practices

- Reusable form systems

- FSC certified plywood

- Minimal waste

- Form oil alternatives

- Recycling programs

Get Started

Free consultation includes:

- Project review

- Forming recommendations

- Cost estimates

- Schedule planning

- Technical support

Call for Quote: (437) 545-0067

Professional forming makes the difference in concrete quality.