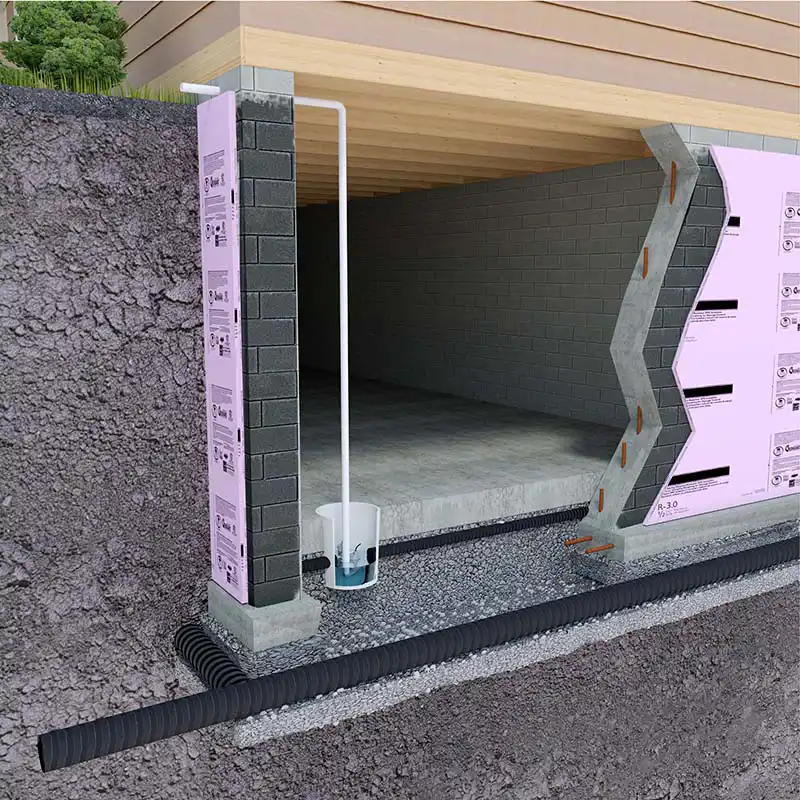

Concrete Strength for Underpinning - Complete Technical Guide

Comprehensive guide to concrete specifications for underpinning - strength requirements (MPa), slump testing, water-cement ratios, quality control, and curing. Learn why 32 MPa matters and how to ensure your foundation concrete meets specifications.

Critical Specifications

Required for Underpinning:

- Strength: 32 MPa minimum

- Slump: 75-100mm (footings)

- Air Content: 6-8% (Toronto)

- W/C Ratio: 0.45 maximum

- Curing: 7 days minimum

Testing Requirements

✓ Slump test every truck

✓ Air content testing

✓ Cylinder tests (3 minimum)

✓ 7 and 28-day breaks

✓ Complete documentation

The Bottom Line

Proper concrete costs 2-3% more but prevents catastrophic failure. Testing costs $300-500 but saves potential $20,000+ in repairs. Never compromise on specifications.

Service Areas

Service Areas: Toronto, North York, Scarborough, Etobicoke, East York, York, Mississauga, Brampton, Vaughan, Richmond Hill, Markham, and surrounding areas.

Remember: Concrete is tested at 28 days, but it serves your home for 100+ years. The specifications you accept today determine your foundation’s performance for generations.