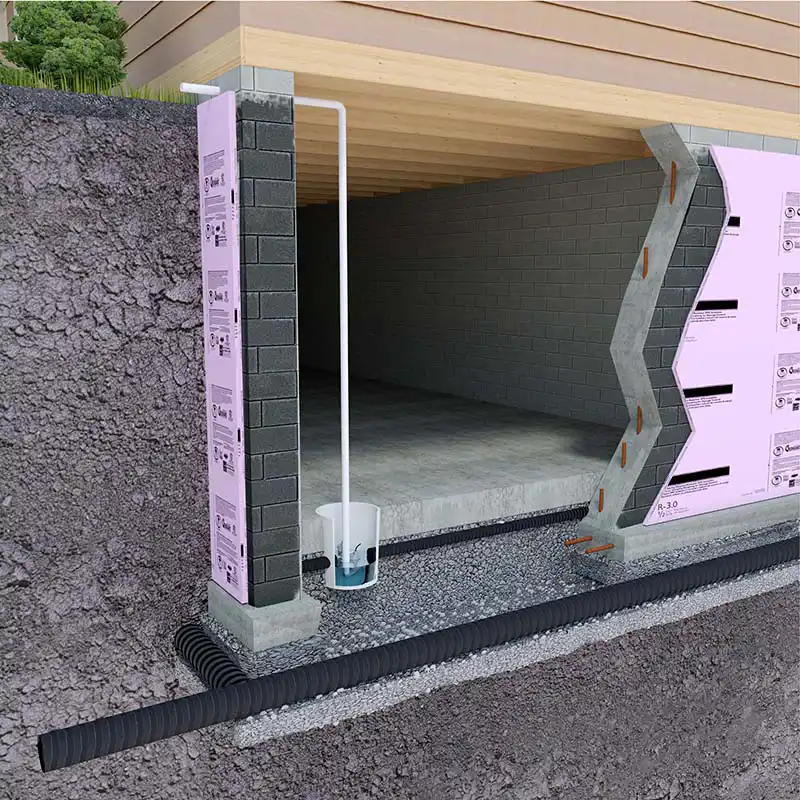

Basement Drainage Complete DIY Guide

Complete guide to installing basement drainage that meets Ontario Building Code. Learn proper pipe types, slope calculations, gravel specifications, and inspection requirements. Professional-grade instructions for DIY drainage installation.

Critical Code Requirements

✓ Minimum 4" diameter pipe

✓ 1% slope minimum (2% recommended)

✓ 6" gravel above and below pipe

✓ Holes face DOWN (not up!)

✓ Purple primer required on PVC

Service Areas

Service Areas: Toronto, North York, Scarborough, Etobicoke, East York, York, Mississauga, Brampton, Vaughan, Richmond Hill, Markham, and surrounding areas.

Drainage is permanent - do it right the first time. When in doubt, consult professionals. The cost of fixing failed drainage far exceeds professional installation.